-Aditee Zalte, Lecturer, MGM IFD

Today in the world of digital printing everyone prefers, from photographers to top industrialist. Digital printing has improved a lot getting fast results. It is more advanced and is a easiest way to print images of your choose. As overall print quality has improved, the implementations of digital printing have also become much easier and clear.

As we know Digital printing methods offer great value for money. It takes less ink, less time and, as a result of this, you have to pay less for printings. Digital printers have also come down a lot in price over the years. Since the digital printing technology in the early nineties, several technologies have been developed. In November 2015 high speed printer’s machinery have been launched. With revised technology and progress in digital printing, cost of digital textile inks has also declined.

Digital printing technology and output is improving continuously. Digital printing is simply transferring a digital file such as a jpeg, pdf, word, excel, photoshop, etc. and then sent to a printer to create a print using CMYK ink. The CMYK process model uses three primary colors of ink: cyan (blue), magenta (red), yellow and key (black) and seven different colors are possible to print colors. There are three common types of digital imaging like inkjet, dye sublimation and laser printers.

The inkjet method uses heat to vaporize and disperse tiny droplets of ink onto the paper surface where it forms a thin film consisting of 0−8 droplets of the CMYK per dot, depending upon the required shade as indicated by the rendering software.

Dye sublimation printers are a heat transfer printing process used mostly for textiles. These printers use only sublimated dyes. Digital images are printed onto heat sensitive papers that are subsequently pressed and heated to transfer the image onto the textile.

Laser printers do not use ink but rather a charged toner that is electrostatically glued to a pattern that is temporarily lased onto the surface of the drum. The charged colorants (toner) stick to the lased pattern on the drum that is subsequently transferred onto the paper as a print.

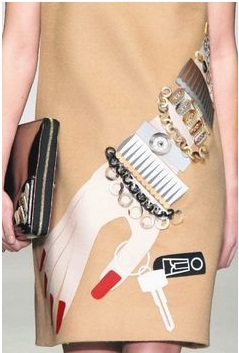

Digital printing machines can print on everything from heavyweight papers to fabric. T-shirt printing is a very popular digital printing application, and some digital printers can print on other fabrics besides T-shirts, including linen and polyester. Some recognizable brand names of Xerox Digital printers include iGen, Iridesse, Versant, Nuvera and PrimeLink production printers.